MD-D50 Auto Stacker for Pails

Keywords:

Food cans, chemical cans production line, packaging machine OEM

DETAILS

Advantages

- Wherever the pail welding seam and handle are before stacking, the welding seam and handle will be neat and in the same direction after stacking.

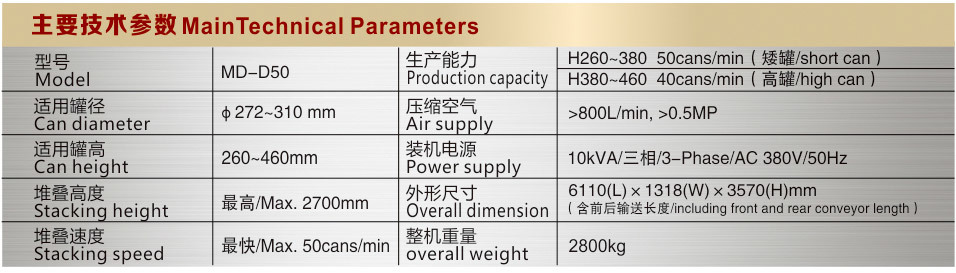

- Adopt second-step stacking function to realize no stop for stack changing, which improves actual staking efficiency. With a highest production capacity of 50 cans/min, it applies to various matching speeds of all production lines at home and abroad.

- Single channel design takes up lttle space.

- Adopt cam reciprocating for can conveying mechanism to ensure flexible and fast running with less noise and longer service life.

- Adopt servo control system for circular motion lifting and flexible belt drive stacking to achieve smooth motion, accurate control and to avoid scratching during stacking. Gear drive and rack drive, etc fail to reach such result.

- Man-machine interface is in English & Chinese and every staking capacity can be set as you like. There is also auto-diagnosis function to ensure safety. Integrated and interlocking control to achieve no-slot joint. One-key for can height adjusting,convenient and rapid in operation.

- Support for Ethernet and remote control.

Related Products

FHZ-500 Automatic Can Body Production Line

This production line applies to auto welding, coating and curing of food, beverage milk cans and aerosol cans with diameter of Φ52 ~ 153mm and height of 50 ~ 320mm.

FHZ-420 Auto Can Body Production Line

This production line applies to auto welding, coating and curing of food and beverage cans with a production capacity of 420 cans/min.

FHZ-300 Auto Can Body Production Line

This production line applies to auto welding, coating and curing of food and beverage cans with a production capacity of 300cans/min.

FHZ-180 Auto Can Body Production Line

This seam welding machine applies to the auto welding of food, milk cans with diameter of Φ 73~153mm and height of 60~310mm.

Messages